If you’re building a clothing brand or managing product sourcing, you’ve probably realized that not all printed T-shirts are created equal. Maybe you’ve dealt with cracking prints after just a few washes. Or suppliers who promised quality but delivered inconsistencies. I’ve been there. That’s why I want to walk you through how custom screen printing really works—what to look for, what to avoid, and how to get it right the first time.

Why Screen Printing Still Dominates in Custom Apparel

Screen printing isn’t new. In fact, it’s been around for decades. But there’s a reason it’s still the top choice for bulk t-shirt printing: it produces rich, lasting colors that pop and hold up over time. Digital printing might be faster for small runs, but when you’re working on custom t-shirts in large volumes or want that premium, tactile finish—screen printing wins.

For our clients—especially those in Europe and North America—screen-printed apparel remains a favorite because it speaks to brand quality. Think sharp logos, clean graphics, and high color fidelity. But again, that only happens if you’ve got the right factory behind the process.

What Separates Good Screen Printing from Bad?

Over the years, I’ve seen a lot of “custom” T-shirts that look great in mockups—but fail in the real world. Here’s what we’ve learned at Sheen from producing thousands of orders:

1. Not All Fabric Is Screen-Friendly

If you’re working with fuzzy or overly textured fabric, don’t expect crisp results. We guide our clients toward 180–240 GSM cotton or cotton-poly blends, which hold ink better and feel better. A smooth surface equals cleaner prints.

2. Ink Type Makes a Difference

We use both plastisol and water-based inks, depending on your needs. Plastisol is vibrant and sits on top of the fabric, ideal for bold logos. Water-based inks soak in and give a softer feel—great for fashion-focused brands.

3. Registration and Curing Are Key

It’s not just about slapping ink on a shirt. If the screens are even slightly off, your design looks blurred. And if the ink isn’t properly cured, it’ll crack or peel fast. We use automatic screen alignment machines and industrial dryers to keep things consistent.

4. Bulk Production Doesn’t Mean Compromised Quality

We’ve designed our process to support both low MOQs (300 pieces) and large orders—up to 20,000 units per month. That means you don’t need to sacrifice quality just because you’re ordering in volume.

Why Work with Sheen for Custom Screen Printing

I get it—there are hundreds of suppliers out there offering custom t-shirts. But not all of them own their production. We do. That gives us full control over what leaves our facility. No finger-pointing, no excuses—just quality results.

Here’s a quick breakdown of how we compare:

| Feature | Sheen (Factory-Based) | Middleman Suppliers |

| Direct Production | ✅ Yes | ❌ No |

| MOQ Flexibility | ✅ 300+ Units | ❌ Usually 1000+ |

| Artwork Assistance | ✅ Included | ❌ Limited |

| Custom Pantone Matching | ✅ Yes | ❌ Not Always |

| Western Market Experience | ✅ U.S., EU, UK | ❌ Generalized |

What we love most is partnering with brands that are scaling—whether you’re a Shopify seller, an independent streetwear brand, or stocking T-shirts for your retail chain. We’ve done it all.

What Happens Next?

So, where do you go from here?

If you’re sourcing screen printed t-shirts for your brand, my advice is simple: don’t compromise on the basics. Fabric, ink, curing, and alignment matter—and they’re worth the investment.

At Sheen, we offer:

- One-on-one consultation (we can hop on a call or video chat if you prefer)

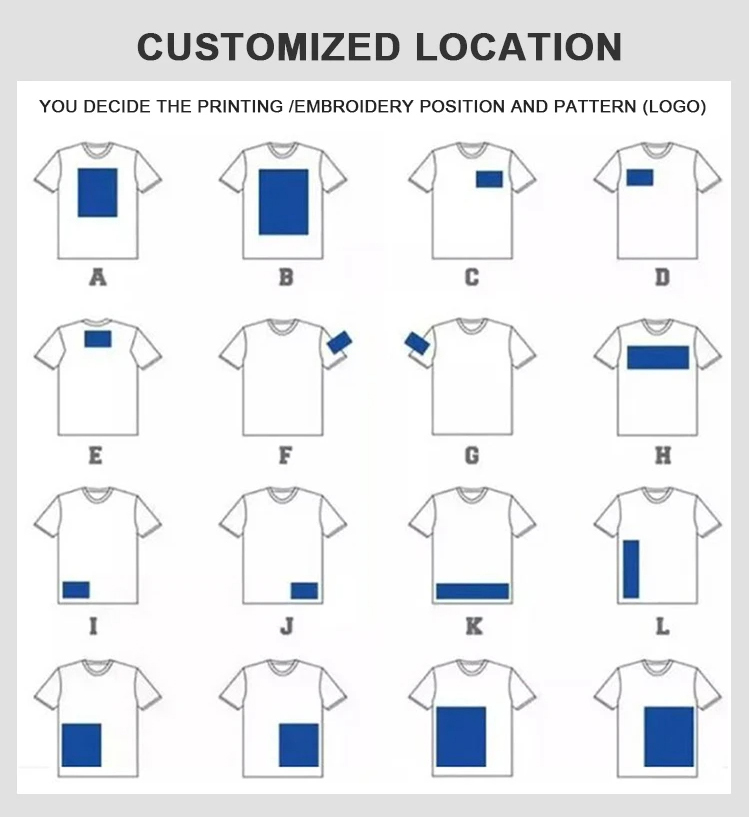

- Multiple print techniques and placements (front, back, sleeves, etc.)

- Transparent pricing and production timelines

- Scalable production without the MOQ pressure

We also support custom packaging, woven labels if needed. Whether you need bulk t-shirts for a merch drop or branded uniforms, we’re ready.

[→ Contact us here to get your project started.]

FAQ: What Our Clients Usually Ask

Q1: What’s the difference between water-based and plastisol inks?

Plastisol sits on top of the fabric, making colors more vibrant and long-lasting. Water-based ink soaks into the fabric for a softer, vintage look. We help you choose based on your design and audience.

Q2: How long do your prints last?

With proper curing, our screen prints last 30+ washes without fading or cracking. We test every batch before shipping.

Q3: Can you help me with design files?

Yes. We accept AI, PSD, PNG, and PDF. If you don’t have production-ready files, we offer artwork assistance.

Q4: Do you accept mixed sizes and colors in one order?

Absolutely. As long as the design stays the same, you can split sizes and base shirt colors in your bulk order.

Q5: What certifications do your materials and inks have?

We work with OEKO-TEX® certified fabrics and offer eco-friendly water-based inks on request. Great for sustainable brands.

What’s Next? Understanding How Fabric Impacts Screen Printing

In our next article, I’ll dig into how fabric composition influences print quality, durability, softness, and shrinkage—especially important when selling to Western consumers who care about feel as much as look. Whether you’re deciding between 100% cotton, tri-blend, or organic materials, you’ll want to read that before placing your next bulk order.