This Trend Is Not Going Away

I remember the moment it clicked. I was at a trade show and every booth—luxury, mid-market, even traditional menswear—displayed hoodies next to tailored jackets. No one was surprised anymore. That was the clearest sign that the athleisure trend had moved from niche to mainstream.

If you buy for stores or manage private-label lines, you’ve probably felt the same nudge: customers want comfort that looks intentional, not sloppy. The fabrics you pick and the silhouettes you develop will decide whether a new drop sells out—or sits in the warehouse.

What’s Driving Fabric and Style Choices Right Now

A few practical forces are steering decisions:

- Lifestyle blending. People work, exercise, and socialize in the same outfit more often now.

- Sustainability pressure. Western buyers want story-backed materials—organic cotton, RPET, bamboo.

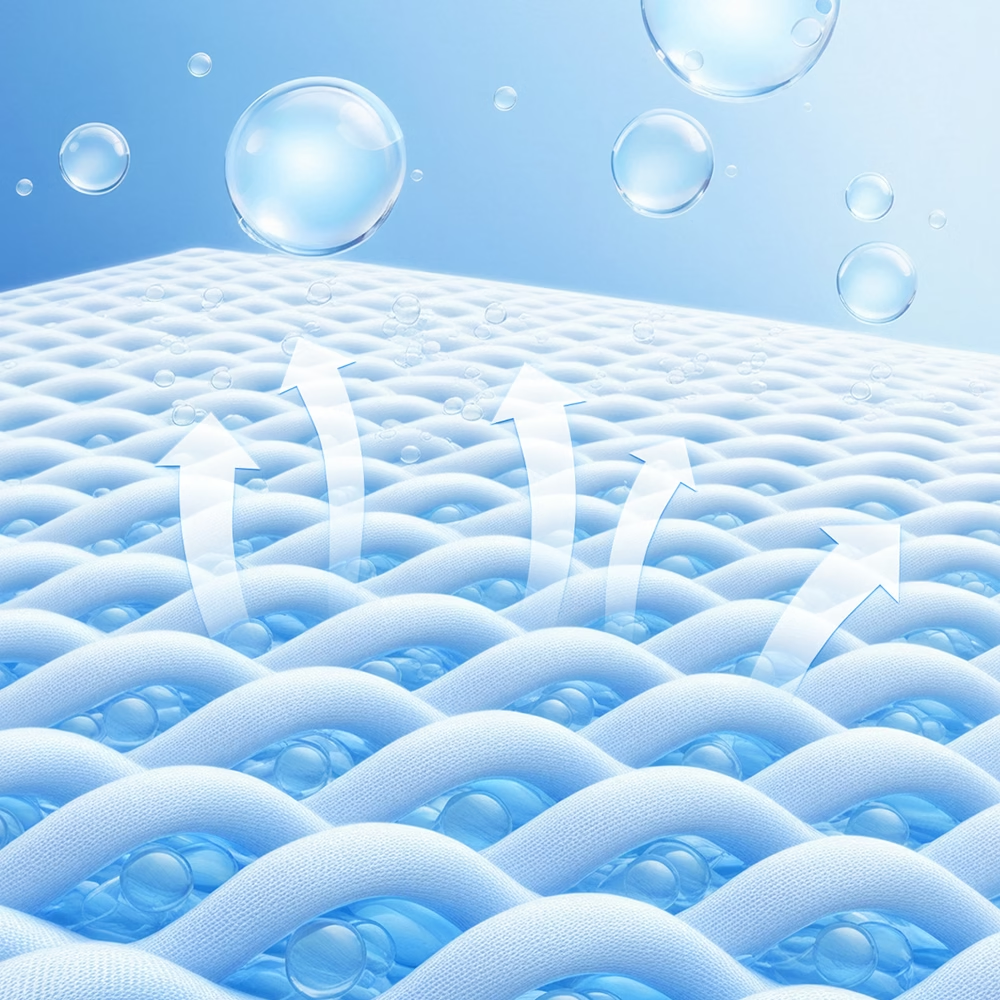

- Performance expectations. Stretch, moisture-wicking, and recoverability are table stakes.

- Retail dynamics. Faster sell-through on comfortable pieces; fewer markdowns.

Put bluntly: buyers want fabrics that feel like activewear but read as everyday clothing. That’s the design brief I get repeatedly.

Fabrics That Buyers Are Choosing (and Why)

Here’s a short, practical rundown of the fabrics I recommend testing first.

Organic cotton blends

Soft hand, good durability, and—crucially—credible certifications (GOTS or OEKO-TEX) matter. A certified organic tee or hoodie can command a better margin in Europe, where shoppers look for proof, not promises.

RPET (recycled polyester)

Solid for shells, outer layers, and leggings. It wears well, dries fast, and is a strong story for sustainable collections. Performance-wise it’s close to virgin polyester, but the environmental message resonates.

Bamboo blends

Surprisingly robust for summer and loungewear—breathable, soft, and naturally odor-resistant. Test shrinkage carefully; good mills control it well.

Stretch knits (elastane blends)

If the item needs recovery—leggings, tapered joggers, fitted tops—elastane is non-negotiable. The trick is balancing stretch with hand-feel; too much spandex makes a garment look cheap.

Silhouettes That Work in Real Retail

Athleisure is as much about shape as it is about fabric. These cuts sell:

- Oversized hoodies and boxy sweatshirts — they read streetwear but pair with clean bottoms.

- Tapered joggers — polished enough for everyday wear, comfortable for movement.

- Cropped sweatshirts and relaxed tanks — perfect for layering under structured jackets.

- Technical leggings with a clean finish — not neon—matte, muted tones perform best on shelves.

I always say: aim for pieces that lock into multiple occasions—commuting, working from home, running errands, hitting a class.

How I Vet Materials and Styles Before I Order

I don’t trust a sample photo. I test, then test again. Here’s the practical checklist I use with clients:

- Pilot runs of 200–300 pcs for any new fabric or cut. Small enough to reduce risk, big enough to read sales patterns.

- Five-wash protocol—check shrinkage, colorfastness, pile, and stretch recovery. If a fabric looks tired after five washes, consumers will notice at scale.

- Wear tests across demographics—get feedback from people who’ll actually buy the product, not just the design team.

- Print and trim checks—does the RPET hold print depth? Does bamboo fray with laser cuts? Small production surprises cost time and margin.

- Certification and chain-of-custody—request batch-linked certificates for organic content or recycled percentages.

A retailer I worked with once trimmed their risk by running two small pilots: one in organic cotton and one in RPET. The organic tee sold steadily; the RPET hoodie outperformed in regions with activewear demand. We then scaled intelligently.

(Internal link: for more on fabric testing, see our post at https://sheenup.com/blog/ — add link here.)

Action — Practical Steps You Can Take Right Now

If you’re planning next season’s buys, do this:

- Pick one core SKU (a hoodie or legging) and run a pilot in one sustainable fabric.

- Insist on wash and performance reports tied to the lot number you’ll buy.

- Negotiate flexible MOQ for trial SKUs. Many mills will split runs if you explain the plan.

- Use sales channels to test—online first, then select store rollouts. Analytics tell you faster than gut feel.

If you want, I can help map an MOQ-friendly pilot plan or share ballpark pricing for organic cotton and RPET pilots. No hard sell—just practical figures and what I’ve seen move in market.

FAQ

1. How do I start testing athleisure fabrics without overcommitting?

Begin with a 200–300 piece pilot for a single SKU. Run wash tests and a short online pre-launch to measure demand.

2. What makes RPET a good choice for athleisure?

RPET performs like virgin polyester for strength and drying, but adds a sustainability story that increasingly matters to Western buyers.

3. How should I evaluate stretch recovery?

Ask suppliers for a 5-wash stretch test. Measure recovery percentage after each wash—anything below a defined tolerance is a red flag.

4. What silhouettes sell best across age groups?

Tapered joggers, oversized tops, and clean-finish leggings have broad appeal. Keep colors muted for wider marketability.

5. What documentation should I request from suppliers?

GOTS/OEKO-TEX for organics, chain-of-custody for recycled content, and batch-linked wash/performance reports.

Final thought and gentle CTA

I’ll be blunt: athleisure isn’t a short-term fad. It’s changed what buyers request and what consumers expect. The safest way to win is slow, smart testing—small pilots, real wash data, credible certificates, and honest supplier conversations.

If you’d like a pilot plan or a shortlist of vetted mills that handle organic cotton, RPET and bamboo well, reach out. I’ll share practical pricing ranges and pilot strategies based on real projects—no boilerplate, just what works.